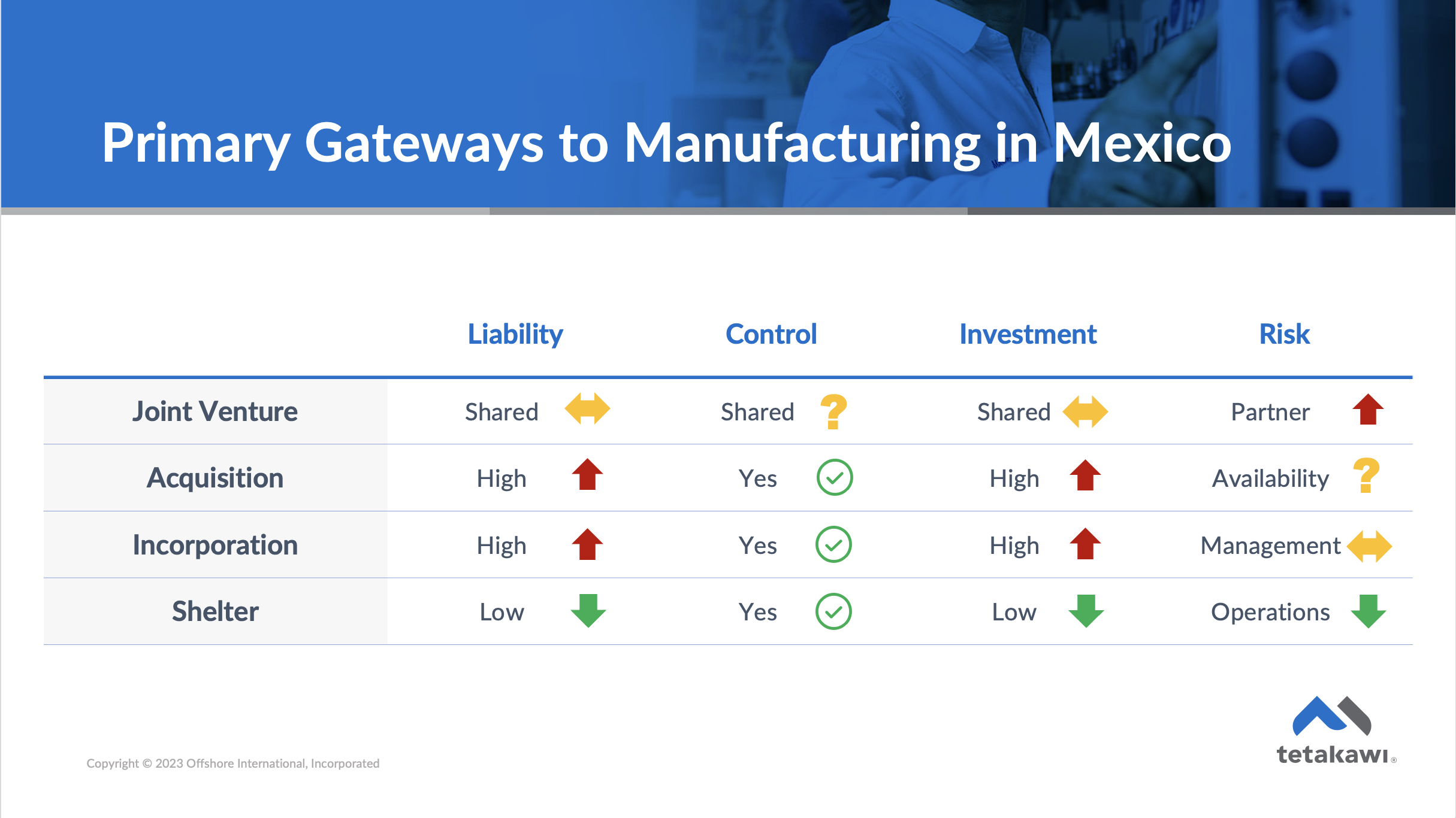

In navigating the complexities of cross-border manufacturing, companies must meticulously assess various entry modes into Mexico to ensure optimal operational efficiency and regulatory compliance. Each mode of entry, whether it be subcontracting, joint ventures, incorporation, or participation in the IMMEX shelter program, presents unique advantages and challenges.

Cross-border manufacturing requires a nuanced approach that balances risk tolerance, cost considerations, speed to market, production control, and feasibility. By leveraging expert guidance from entities like Tetakawi, businesses can navigate the intricacies of cross-border manufacturing, identify the most suitable mode of entry, and establish a robust operational framework for sustained success in the Mexican market.

To help determine the right strategy for your organization, we have also listed below a few factors to consider for each of these four modes of entry into Mexico.

1. Contract Manufacturing in Mexico

Outsourcing or sub-contracting manufacturing to a third-party manufacturing vendor is a familiar model that works in many countries. It's a rapid way to launch operations, as this mode of entry depends upon a company already being established in specific manufacturing processes. The subcontractor typically bears the legal and compliance risks of operating in Mexico. The trade-off is that this option can command a higher cost.

There are some challenges with this mode of entry in Mexico. First, there may not be a subcontractor that supports your specific manufacturing needs. Second, many of the subcontractors that do operate in Mexico lack the financial viability needed to support a high level of credit and investment, as may be found in other countries. Last, subcontractors in Mexico may have less need for your company's distribution services as compared to subcontractors in other countries. This can potentially lead to higher pricing.

In general, contract manufacturing in Mexico works best for companies that need low-volume products utilizing straightforward processes, such as stamping or injection molding. Companies with high volumes or that need to protect processes and product information from potential competitors may benefit less from contract manufacturing.

2. Joint Ventures and Acquisitions

Mexico is very open to foreign investment, and foreign investors do in fact, own Mexican companies in virtually every industry. Joint ventures can be set up in virtually any type of arrangement. An advantage of this mode of entry is that it generally comes with expertise, talent, and some amount of operational space, making it a quick mode from which to launch.

The biggest challenge is finding the right fit. Companies that have identified a target or have a working relationship with a company that seems to have a similar approach, vision, or culture are best suited to this mode of manufacturing in Mexico. Even then, it's important for companies to avoid common mistakes when exploring the possibility of joint ventures or acquisitions in Mexico, including:

- Prioritizing acquisition or joint venture without a target in mind: Planning for this mode of entry as a primary strategy, without knowing whether you can find a target, can mean dedicating significant time to this search—and potentially coming up empty-handed.

- Lack of due diligence: There's a significant amount of due diligence that's required prior to an acquisition. This can be particularly challenging for smaller companies that may need more documents to support easy due diligence, such as GAAP documents and the like.

- Not accounting for the union relationship: If you're targeting the acquisition of a company that has a complicated union relationship, you face the added risk that might not be readily apparent during your due diligence processes.

3. Forming a Subsidiary in Mexico

Incorporating in Mexico follows a process similar to that found in many other countries, including the United States. The most significant difference is that Mexico defines the purpose of corporations narrowly. That means manufacturers can potentially run into situations where they need more than one corporation to accomplish everything they want to do.

It's essential to be clear upfront about the correct formation. For example, some companies set up a non-IMMEX corporation to issue a Mexican invoice and sell directly in Mexico, which requires them to collect value-added tax and pay it. However, they could secure greater value by establishing an IMMEX corporation for the bulk of their production, avoiding value-added tax, and earning participation in export programs, including exporting within Mexico to other exporting companies. They can then establish a trading company to perform the transactions necessary to invoice in Mexico.

Overall, however, it's relatively easy and inexpensive to incorporate in Mexico, although the corporation is then responsible for any investment and operation expenses. In general, corporations can often be set up in two to three months, although certification may take longer for IMMEX corporations. The biggest trade-off is that any risk is placed solely upon the corporation and any shareholders.

4. IMMEX Shelter Company

The IMMEX shelter program is unique to Mexico. Its goal is to make it easy for foreign companies to enter the Mexican market by minimizing the legal and regulatory requirements of operating in a foreign country. The program allows a foreign company to operate under the legal umbrella of a company that is registered with the Mexican government and identified as a shelter provider. The foreign company does not have permanent establishment in Mexico and so is not directly liable for legal or regulatory compliance. Yet they can operate as if they did have permanent establishment.

There are certain requirements IMMEX-registered companies must meet. In fact, the process of IMMEX registration can be lengthy for foreign corporations doing this on their own. In addition, to avoid the payment of value-added tax or, if they have to pay it, to recover that value-added tax, goods must be exported outside of Mexico. Alternatively, it is possible to export between IMMEX companies within Mexico.

Because the IMMEX-certified company has a legal presence in Mexico, they hold responsibility for certain administrative tasks. For example, hiring must be done by a legal entity in Mexico. As a result, the shelter company administers hiring, registering with the government, making sure that the taxes are paid, and similar activities. Generally, shelter companies provide expertise in these areas that can further support manufacturers' successful speed to market. In addition, manufacturers retain full control of their operational processes.

A shelter model offers tremendous benefits, but it may not make sense for every company. Many companies are attracted to the shelter model because of the cost savings it affords, generated through economies of scale in serving a wide range of clients. Companies with fewer than 20 people may be too small to be viable under this mode of entry, while companies with more than 500 people may not see these bottom-line benefits. However, there are exceptions to these rules, as some larger companies find the service support to be beneficial and prefer the reduced risk.

Find the mode of entry that's right for your company

Not sure which of these modes of entry might work best for your organization? Below are five factors that every company should consider before making a decision.

- Risk tolerance: There are risks venturing into any unknown, including financial, legal, regulatory, and technical risks. Understanding your comfort level can help determine the appropriate operational strategy for you.

- Cost: Look beyond the upfront cost of your investment to consider the ongoing operating costs as well.

- Speed to market: How quickly do you need a solution to be up and running in order to meet market demands?

- Production control: There are a number of controls to consider, and different modes of entry will provide different levels of control over processes.

- Feasibility and viability: Even if you find a preferred solution, there may be factors beyond your control.

To learn more, listen to this and other Manufacturing in Mexico podcasts, or reach out to a Tetakawi expert to discuss your options.

Subscribe

Sign up and stay informed with tips, updates, and best practices for manufacturing in Mexico.